CloseTutorial video

DESIGN FOR ASSEMBLY

Benefits: Significantly reduce product cost and improve reliability

Strategy: Design the product to be easy to assemble

Design for Assembly (DFA) is a product development strategy that can substantially reduce total product cost and improve reliability without compromising a product’s functionality. This approach focuses on simplifying the product structure to make assembly easier, faster, and more cost-effective. Unlike traditional cost reduction strategies that primarily target individual part costs, DFA emphasizes the overall assembly process, leading to more significant and sustainable cost savings.

Since the 1980s, hundreds of companies have achieved an average product cost savings of 50% through Product Simplification—a core principle of DFA. This methodology has been successfully applied across various industries, including automobiles, electronics, consumer goods, medical devices, industrial equipment, and aerospace, demonstrating its versatility and effectiveness in enhancing product competitiveness.

Why Should I Care About Assembly Labor?

A common product cost reduction strategy involves designing individual parts to be simpler, easier to manufacture, and less expensive to produce. Engineers often focus intensely on minimizing part costs, believing that reducing the cost of each component will lead to overall product savings. However, this approach can be misleading.

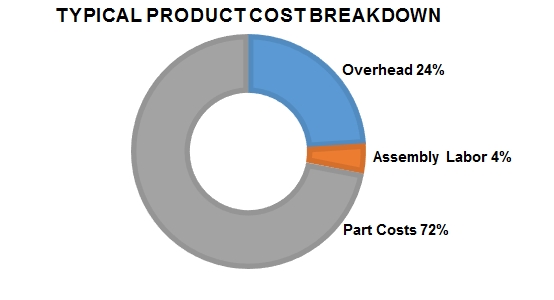

Typical Product Cost Breakdown:

The reality is that focusing solely on part costs can inadvertently lead to a higher total product cost compared to strategies that emphasize minimizing assembly labor. This counterintuitive outcome arises because designing parts to be easy to manufacture often results in an increased total number of parts. Conversely, designing a product to be easy to assemble typically reduces the number of parts required.

Industry research has demonstrated that, thanks to modern manufacturing techniques, using fewer parts is frequently less expensive than utilizing a large number of inexpensive parts. Additionally, a reduced part count offers several advantages:

- Ease of Service: Fewer parts simplify maintenance and repairs, reducing service time and costs.

- Reduced Defects: With fewer components, the likelihood of defects decreases, enhancing overall product quality.

- Increased Reliability: Simplified assemblies are generally more reliable over the product's lifetime.

Ultimately, Product Simplification ensures that more value is captured by both the manufacturer and the consumer, fostering a win-win scenario where products are both affordable and dependable.

How Do I Execute This Strategy?

In theory, designing a product with fewer parts and simpler assemblies seems straightforward. However, in practice, many finished designs remain inefficient because the product development team either lacks sufficient time or does not recognize which parts should be combined. To effectively execute the DFA strategy, the following steps are essential:

1. Early Integration of DFA Software

The early use of Design for Manufacture and Assembly (DFMA) software is critical. DFA software components quantify assembly efficiency and provide actionable suggestions for redesigning products to enhance performance and reduce part counts. By analyzing the current design, DFA tools can identify opportunities for part consolidation and simplification.

2. Assembly Efficiency Quantification

DFA software evaluates the assembly process, identifying bottlenecks and inefficiencies. It measures factors such as the number of assembly steps, the time required for each step, and the potential for automation. This quantitative analysis helps in making informed decisions about which aspects of the design can be improved to streamline assembly.

3. Redesign Suggestions

Based on the analysis, DFA tools offer redesign suggestions that aim to reduce the number of parts and simplify the assembly process. These suggestions often lead to improvements in product performance, as simpler designs are typically more robust and easier to use.

4. Calculating the Theoretical Minimum Number of Parts

DFA software calculates the theoretical minimum number of parts required for the product. This calculation provides a benchmark for designers, highlighting the maximum potential for part consolidation. Understanding the minimum part count helps teams set realistic goals for design simplification.

5. Cost Comparison with DFM Software

Once DFA redesigns are proposed, the should-cost of each iteration can be quickly compared using Design for Manufacture (DFM) software components. By integrating DFA and DFM tools, development teams can assess the cost implications of design changes in real-time, ensuring that cost reduction goals are met without sacrificing quality or functionality.

6. Iterative Design Refinement

Design teams should engage in an iterative process, continuously refining the product design based on feedback from DFA and DFM analyses. This iterative approach ensures that the final product design is optimized for both assembly efficiency and manufacturing cost-effectiveness.

Implementing Design for Assembly in Your Organization

1. Foster a Collaborative Culture

Encourage collaboration and open communication between design, manufacturing, and assembly teams. Promoting mutual respect and understanding of each team's expertise ensures that assembly considerations are integrated into the design process from the outset.

2. Invest in Training and Tools

Provide training to team members on DFA principles, methodologies, and software tools. Investing in advanced DFMA software equips teams with the resources they need to effectively simplify product designs and optimize assembly processes.

3. Establish Clear Processes and Standards

Develop and implement clear processes and standards for DFA. Define roles and responsibilities, establish standardized procedures for design and assembly collaboration, and set clear expectations for part consolidation and assembly efficiency.

4. Utilize Cross-Functional Teams

Create cross-functional teams that include members from design, manufacturing, engineering, and assembly departments. These teams facilitate the exchange of diverse perspectives and expertise, leading to more comprehensive and optimized product designs.

5. Continuously Monitor and Improve

Regularly review and assess the effectiveness of the DFA process. Gather feedback from team members, analyze performance metrics, and identify areas for improvement. Embrace a mindset of continuous improvement, seeking out innovative solutions and best practices that can enhance the DFA strategy and drive ongoing cost reductions and efficiency gains.

Conclusion

Design for Assembly is a transformative strategy for companies aiming to develop cost-effective, reliable, and high-quality products. By focusing on simplifying product designs and optimizing the assembly process, organizations can achieve significant cost savings, enhance product reliability, and improve overall competitiveness in the market.

Implementing DFA requires a commitment to collaboration, continuous improvement, and strategic decision-making. However, the substantial benefits—ranging from reduced manufacturing costs and improved reliability to increased customer satisfaction—make it an invaluable approach for any forward-thinking organization.

Embracing Design for Assembly not only streamlines the production process but also positions companies to better meet market demands, respond to customer needs, and achieve long-term success in an ever-evolving business landscape.

DESIGN FOR MANUFACTURING

Benefits: Design cost-effective parts and products during the early stages of development

Strategy: Break the walls that exist between design and manufacturing

Design for Manufacturing (DFM) is a product development strategy that allows companies to anticipate and influence manufacturing costs during the earliest stages of product development. Since it is widely accepted that over 70% of product cost is locked-in during the design phase, it is extremely important that designers and manufacturers collaborate to ensure total product cost goals will be met. The problem is that the typical product development team operates in a “toss it over the wall” fashion. That is to say that the design team is sitting on one side of a wall and the manufacturing team on the other. Once the design is finished, it gets tossed to the manufacturing team in a manner that doesn’t allow for any collaboration. A first-class product development team will instead implement Product Costing to avoid lengthy re-design efforts and missed cost reduction opportunities that result from the more typical approach.

What does an effective Design for Manufacturing process look like?

The first stage of Design for Manufacturing is where the design engineers provide specifications for the parts they have decided to include in the product structure. Ideally, a Product Simplification strategy will have been used to help achieve this. Using these part design specifications, the manufacturing engineers can provide feedback as to what is actually involved in bringing the designs to life. This combination of design and manufacturing information allows for accurate cost estimates to be generated in DFM Concurrent Costing software. At this point, the designers go back to their initial proposals and finalize the selection of processes and materials, as well as fine-tune the parameters of each design. The goal is to achieve the lowest cost design for each finalized part that is still able to meet the functional requirements of the product.

What benefits does DFM Concurrent Costing provide during this process?

Besides providing real-time accurate cost estimates, DFM Concurrent Costing serves as the focal point of communication between designers and manufacturers. DFM identifies the major cost drivers for each manufacturing process so that both manufacturing and design can ask the essential cost-related questions at the most relevant time. This results in a faster product development process because there are fewer problems to address during the latter stages of development. With Product Costing, product development becomes a more focused and educated effort than previously.

What an Effective Design for Manufacturing Process Looks Like

An effective DFM process is characterized by its structured approach, collaborative environment, and continuous improvement ethos. Below are the key elements that define an effective DFM process.

Integrated Teams

Successful DFM relies on integrated teams where designers, manufacturing engineers, and other stakeholders work collaboratively from the outset. This integration ensures that all perspectives are considered, leading to more holistic and optimized designs.

Iterative Feedback Loops

Continuous feedback loops between design and manufacturing teams facilitate ongoing improvements and refinements. Iterative feedback allows for the identification and resolution of issues in real-time, enhancing the overall quality and cost-effectiveness of the product.

Advanced Costing Tools

Utilizing advanced costing tools, such as DFM Concurrent Costing software, provides accurate and real-time cost estimates. These tools enable teams to make informed decisions based on comprehensive cost analyses, ensuring that budgetary goals are met without compromising on quality.

Standardized Processes

Standardizing design and manufacturing processes promotes consistency, efficiency, and scalability. Standardization reduces variability, minimizes errors, and facilitates easier training and onboarding of new team members.

Continuous Improvement

An effective DFM process embraces a culture of continuous improvement, encouraging teams to seek out and implement innovative solutions that enhance manufacturing efficiency and reduce costs. This proactive approach ensures that the DFM process remains dynamic and adaptable to evolving market demands and technological advancements.

DFM Concurrent Costing: Enhancing Communication and Cost Management

Real-Time Accurate Cost Estimates

One of the primary advantages of DFM Concurrent Costing is its ability to generate real-time, accurate cost estimates. By integrating design and manufacturing data, Concurrent Costing software provides immediate feedback on the cost implications of design choices. This real-time visibility enables teams to make informed decisions swiftly, ensuring that cost objectives are met without delaying the development process.

Focal Point of Communication

DFM Concurrent Costing serves as the central hub for communication between designers and manufacturers. It facilitates the exchange of vital information, ensuring that both teams are aligned in their cost reduction and efficiency goals. This centralized communication platform minimizes misunderstandings and fosters a collaborative environment where cost-related issues can be addressed promptly and effectively.

Identification of Major Cost Drivers

DFM Concurrent Costing tools are adept at identifying the major cost drivers associated with each manufacturing process. By pinpointing these key factors, teams can focus their efforts on areas that offer the most significant cost-saving opportunities. Understanding cost drivers allows for targeted interventions and strategic planning, enhancing overall cost management.

Timely Cost-Related Queries

With DFM Concurrent Costing, design and manufacturing teams can raise essential cost-related questions at the most relevant times in the development cycle. This timely inquiry ensures that cost considerations are integrated into the decision-making process, preventing costly oversights and enabling proactive cost management.

Accelerated Product Development

The streamlined communication and accurate cost management facilitated by DFM Concurrent Costing result in a faster product development process. By reducing the number of issues that need to be addressed in the later stages of development, teams can avoid delays and keep the project on track. This acceleration is crucial in competitive markets where time-to-market can significantly impact a product's success.

Focused and Educated Product Development

DFM Concurrent Costing transforms product development into a more focused and educated effort. Teams are equipped with the necessary tools and information to make strategic decisions that align with cost and quality objectives. This informed approach enhances the overall efficiency and effectiveness of the product development process, leading to better outcomes and higher-quality products.

Implementing Design for Manufacturing in Your Organization

Foster a Collaborative Culture

Encourage a culture of collaboration and open communication between design and manufacturing teams. Promote mutual respect and understanding of each team's expertise and contributions. Regular cross-functional meetings and joint training sessions can help build strong working relationships and enhance team cohesion.

Invest in Training and Tools

Provide training to team members on DFM principles, methodologies, and tools. Investing in advanced DFM software, such as Concurrent Costing tools, equips teams with the resources they need to effectively integrate design and manufacturing processes. Continuous learning and development ensure that teams remain adept at leveraging DFM strategies to their fullest potential.

Establish Clear Processes and Standards

Develop and implement clear processes and standards for DFM. Define roles and responsibilities, establish standardized procedures for design and manufacturing collaboration, and set clear expectations for cost management and quality assurance. Consistent processes and standards promote efficiency and ensure that all team members are aligned in their efforts.

Utilize Cross-Functional Teams

Create cross-functional teams that include members from design, manufacturing, engineering, and other relevant departments. These teams facilitate the exchange of diverse perspectives and expertise, leading to more comprehensive and optimized product designs. Cross-functional collaboration is essential for identifying and addressing potential manufacturing challenges early in the development process.

Continuously Monitor and Improve

Regularly review and assess the effectiveness of the DFM process. Gather feedback from team members, analyze performance metrics, and identify areas for improvement. Embrace a mindset of continuous improvement, seeking out innovative solutions and best practices that can enhance the DFM strategy and drive ongoing cost reductions and efficiency gains.

Conclusion

Design for Manufacturing is an indispensable strategy for companies aiming to develop cost-effective, high-quality products in a competitive market. By fostering collaboration between design and manufacturing teams, implementing robust product costing methodologies, and utilizing advanced tools like DFM Concurrent Costing software, organizations can significantly reduce manufacturing costs, accelerate product development, and enhance overall product quality.

Adopting DFM requires a cultural shift towards integrated teamwork, continuous improvement, and strategic decision-making. However, the benefits—ranging from cost savings and faster time to market to improved product quality and increased innovation—make it a worthwhile investment for any forward-thinking organization.

Embracing Design for Manufacturing not only optimizes the production process but also positions companies to better meet market demands, respond to customer needs, and achieve long-term success in an ever-evolving business landscape.

SHOULD COST ANALYSIS

Benefits: Achieve cost reduction by reducing the prices you pay for parts and products

Strategy: Use data-driven discussion to base cost targets and negotiation on true manufacturing costs

Should Cost Analysis is a strategic cost management approach aimed at reducing the prices paid for parts and products by establishing cost reduction goals based on an accurate understanding of true manufacturing costs. Unlike arbitrary price cuts that may undermine supplier relationships and leave potential savings untapped, Should Cost Analysis provides a data-driven foundation for negotiations, ensuring that cost targets are realistic and achievable.

Typically, management sets cost reduction targets and expects suppliers to meet these reductions without a comprehensive analysis of the underlying manufacturing costs. This often leads to unrealistic price demands that can strain supplier relationships and potentially drive cost-competitive suppliers out of business. A more effective strategy involves comparing supplier price quotes against independent estimates of the true manufacturing costs, fostering informed discussions aimed at understanding and bridging any cost discrepancies.

The Important Difference Between Price and Cost Information

A common pitfall in cost estimation is the reliance on historical price data. Historical pricing does not accurately reflect the current cost structure faced by suppliers when manufacturing new parts. This discrepancy can misguide negotiation efforts, directing focus toward areas with limited savings potential while overlooking significant cost-saving opportunities where suppliers may be overcharging.

To mitigate this, Should Cost Analysis eliminates the influence of historical prices, ensuring that negotiations are centered solely on the profit margin. By understanding the true cost to the supplier, organizations can identify genuine opportunities for cost reduction and foster fairer, more sustainable supplier relationships.

Negotiating with Suppliers Using DFM Concurrent Costing

DFM Concurrent Costing is an invaluable tool in the Should Cost Analysis process, enabling organizations to generate precise cost estimates in real-time. By focusing exclusively on the factors that genuinely drive manufacturing costs, DFM Concurrent Costing allows companies to assess whether a supplier’s quote is reasonable and justified.

The software translates complex cost data into a format that suppliers readily understand, eliminating disputes over estimate methodologies. This transparency fosters a fair and open Supplier Costing process, laying the groundwork for a sustainable and resilient supply chain.

Key Components of Should Cost Analysis

Effective Should Cost Analysis encompasses several critical components that collectively ensure accurate cost estimation and successful cost reduction:

- Independent Cost Estimation: Develop an unbiased estimate of the manufacturing cost based on current data and industry standards.

- Cost Driver Identification: Pinpoint the primary factors that influence manufacturing costs, such as materials, labor, and overhead.

- Supplier Collaboration: Engage in transparent discussions with suppliers to understand their cost structures and identify areas for cost savings.

- Data-Driven Negotiations: Base negotiation strategies on accurate cost data rather than arbitrary price targets.

- Continuous Monitoring: Regularly review and update cost estimates to reflect changes in manufacturing processes and market conditions.

Implementing Should Cost Analysis in Your Organization

To successfully implement Should Cost Analysis, organizations should follow these best practices:

1. Establish a Cross-Functional Team

Create a team that includes members from procurement, engineering, finance, and manufacturing. This diverse team ensures a comprehensive understanding of all cost factors and facilitates effective collaboration with suppliers.

2. Invest in Advanced Costing Tools

Utilize sophisticated costing software, such as DFM Concurrent Costing, to generate accurate and real-time cost estimates. These tools provide the necessary data to support informed negotiations and strategic decision-making.

3. Develop Detailed Cost Models

Create detailed models that break down the cost components of each part or product. These models serve as a foundation for comparing supplier quotes and identifying cost-saving opportunities.

4. Train Your Team

Provide training on Should Cost Analysis methodologies and tools. Ensuring that your team is well-versed in these techniques enhances the effectiveness of your cost reduction efforts.

5. Foster Transparent Supplier Relationships

Build strong, transparent relationships with suppliers based on mutual trust and understanding. Open communication channels facilitate the sharing of cost-related information and collaborative problem-solving.

6. Monitor and Adjust

Continuously monitor cost performance and adjust strategies as needed. Staying adaptable ensures that your Should Cost Analysis remains effective in the face of changing market conditions and evolving manufacturing processes.

Benefits of Implementing Should Cost Analysis

- Cost Reduction: Achieve significant savings by negotiating prices based on true manufacturing costs rather than arbitrary targets.

- Improved Supplier Relationships: Foster collaborative partnerships with suppliers built on transparency and mutual understanding.

- Enhanced Negotiation Power: Arm your team with accurate cost data to drive more effective and informed negotiations.

- Increased Profit Margins: Reduce the cost of parts and products, thereby enhancing overall profitability.

- Supply Chain Resilience: Develop a sustainable supply chain by ensuring that suppliers remain competitive and financially stable.

Conclusion

Should Cost Analysis is a transformative cost management strategy that empowers organizations to achieve meaningful cost reductions by basing price negotiations on an accurate understanding of true manufacturing costs. By leveraging tools like DFM Concurrent Costing and fostering transparent, data-driven discussions with suppliers, companies can not only reduce expenses but also build stronger, more resilient supply chains.

Implementing Should Cost Analysis requires a strategic commitment to data accuracy, cross-functional collaboration, and continuous improvement. However, the benefits—ranging from significant cost savings and improved profit margins to enhanced supplier relationships and supply chain stability—make it an essential practice for any organization striving for long-term success and competitiveness in today’s dynamic market environment.

Unlocking the Power of Design for Assembly

Unlocking the Power of Design for Assembly