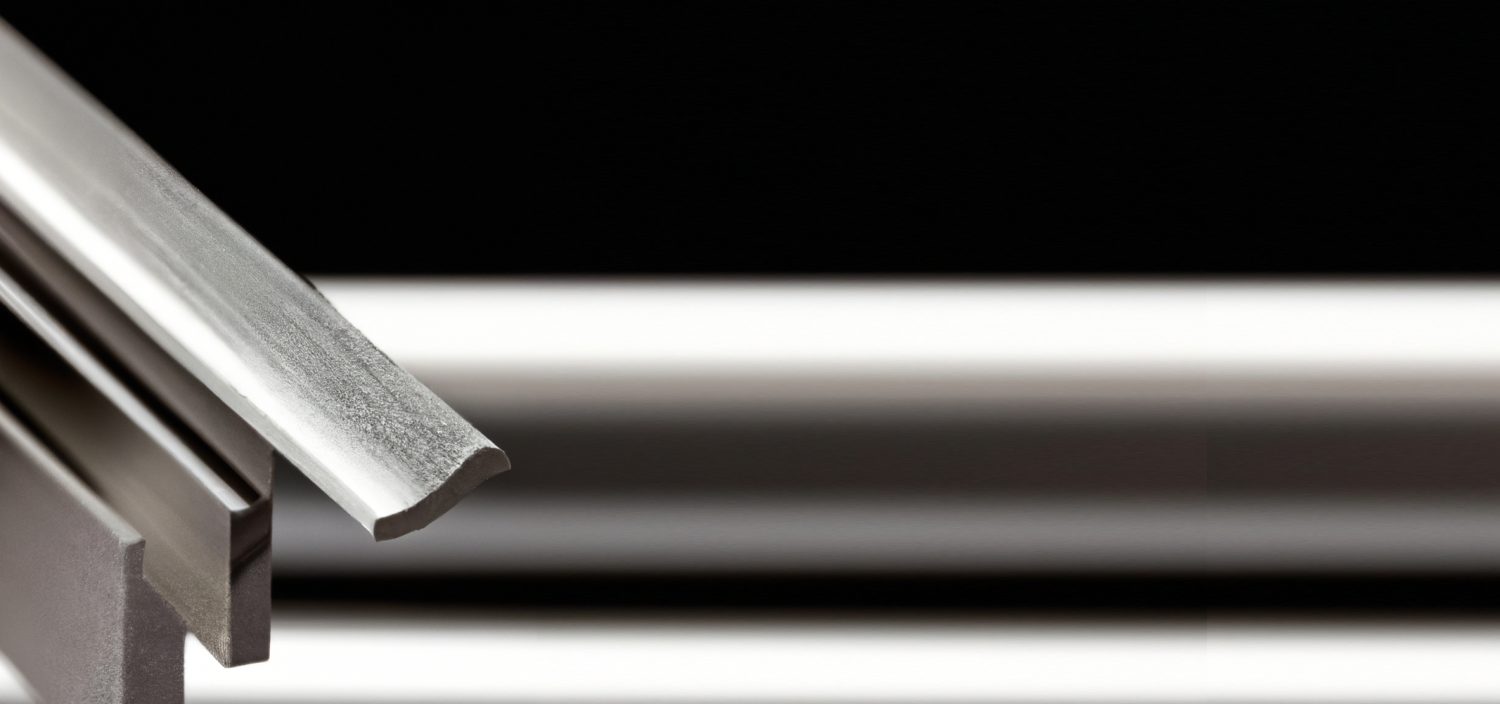

Optimizing Aluminum Extrusion with Advanced DFMA® Software Techniques

Aluminum extrusion has been an important part of the manufacturing sector for over a half century. It is a versatile manufacturing process that caters to a wide range of industries due to its unique combination of flexibility, strength, and lightweight properties. Yet until recently, a truly robust method for simulating and optimizing the cost of these parts did not exist.

Here's a list of industries and some of the products within them that use aluminum extrusion:

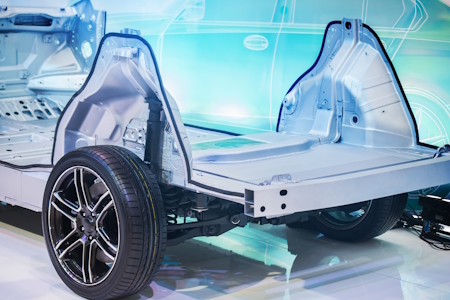

Automotive:

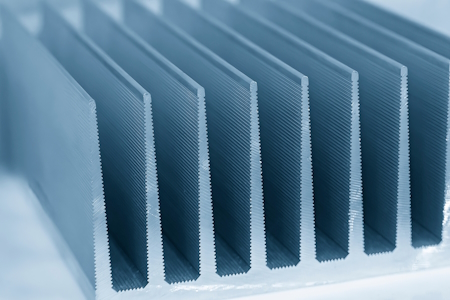

Heat sink

- Structural components (e.g., chassis, crash structures)

- Heat sinks for cooling systems

- Trim and decorative parts

- Roof rails and running boards

- Electrical components

Aerospace:

- Airframe structural components

- Seat tracks

- Flooring systems

Electronics:

- Heat sinks for CPUs and LEDs

- Casings and chassis for electronics

- Connector and housing parts

Transportation:

Automotive chassis

- Airframe structural components

- Seat tracks

- Flooring systems

- Roof rails and running boards

- Electrical components

Transportation:

- Structural components for trains and trams

- Marine applications such as hull reinforcements

- Components for bicycles and motorcycles

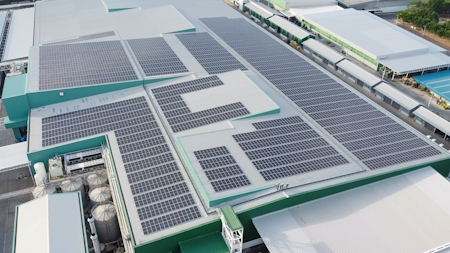

Energy:

- Frames for solar panels

- Wind turbine components

- Electric power transmission components

Consumer Goods:

- Frames for furniture (e.g., tables, chairs)

- Appliance structures (e.g., refrigerator frames)

- Sporting goods (e.g., tent poles, bicycle frames)

Industrial Equipment and Machinery:

Solar Panel Framing

- Conveyor systems

- Protective barriers and enclosures

- Assembly jigs and fixtures

Medical Equipment:

- Frames for wheelchairs and walkers

- Medical bed structures

- Equipment housing

Telecommunications:

- Antenna structures

- Housing for communication devices

DFMA® Software: Redefining the Cost Modeling Landscape for Extrusion

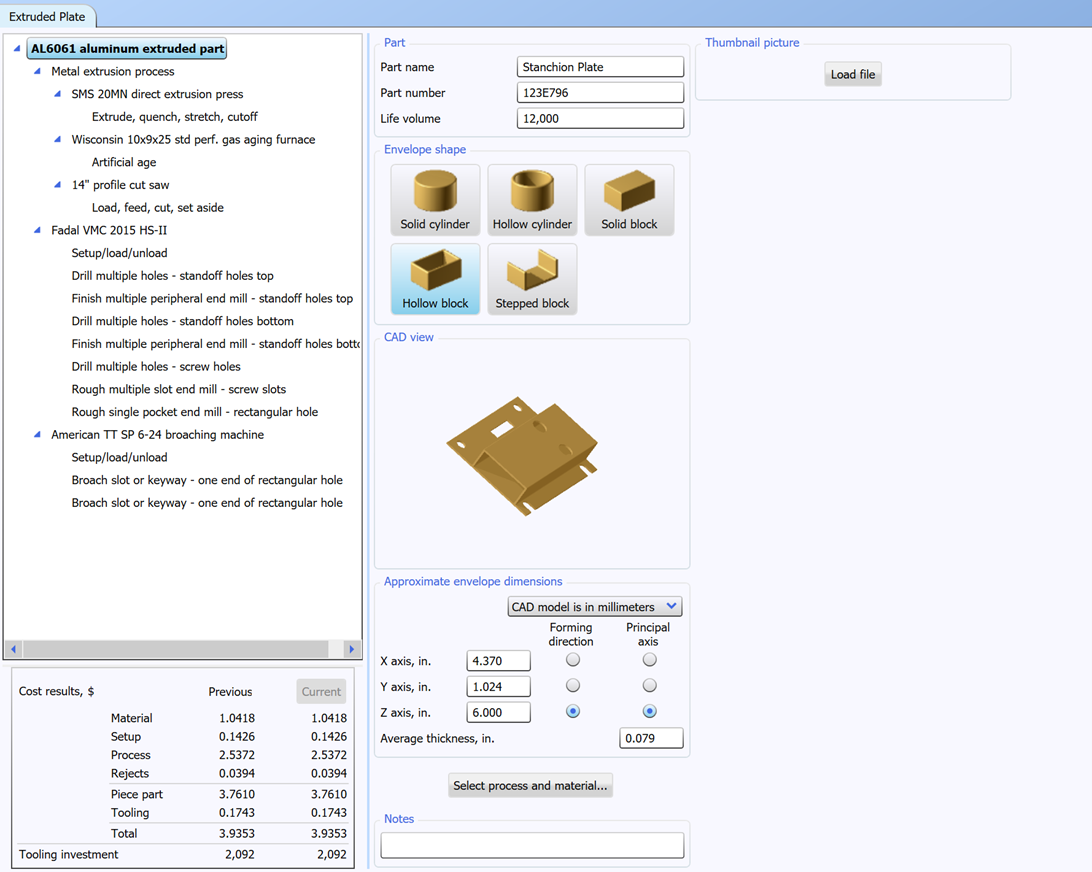

Due to such widespread use of this process, a robust cost model has been in high demand for some time. The demand was recently met following extensive research conducted at Boothroyd Dewhurst. DFM Concurrent Costing® software now allows design and cost engineers to import CAD models or simple geometry and easily generate accurate should-costs for this critical process. A variety of major materials and machines are included, as well as the ability to compare the economics with the choice of using other processes.

The software analyzes the design parameters prior to or after a 3D model has been developed.

Advanced Optimization Capabilities

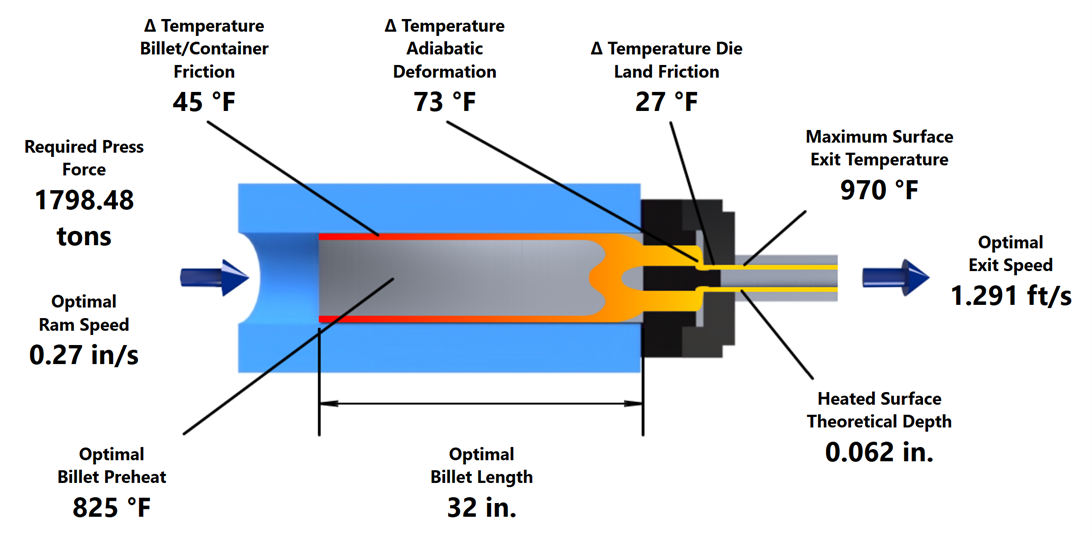

Not only does this new cost model contain all the rigor of the existing models in DFM, but it also introduces a more advanced simulation capability. It cycles through all the optimal manufacturing parameters (billet length, ram speed, preheat temp, exit speed, etc.) that will achieve the lowest cost extrusion possible. This goes beyond the benefits of design to cost by essentially designing the process for cost. It fits very well into the overall goal of DFMA®, which is to achieve the same functionality at the lowest cost possible.

The Benefits for Cost Engineers/Procurement:

The optimal parameters for this manufacturing process have been meticulously curated and are now showcased in a dedicated, process-specific report. This comprehensive document serves not just as a summary of costs but as a holistic representation of the intricate details associated with your production process. With this report in hand, you can ensure that your cost simulations are consistently aligned with the techniques and strategies employed by your supplier. By grounding your discussions in tangible data, it offers a robust foundation for negotiations. This data-driven approach not only fosters transparency and trust but also ensures that negotiations are rooted in reality, paving the way for mutually beneficial outcomes for all parties involved.

The new Metal Extrusion process specific report.

In Conclusion

The fusion of new technology and traditional manufacturing processes, as exemplified by the integration of DFMA® software with aluminum extrusion, signifies a promising trajectory for the many users of this process. These strides promote a pivotal shift towards smarter, data-driven product development and procurement strategies. A process that has long existed in the analog world now has a digital twin, which can enable new levels of cost efficiency for the diverse group of industry users we have highlighted above.