|

A Level-Headed Approach to Costing and Machining Aztalan Engineering uses DFMA to quote costs, analyze designs, implement process controls, and communicate with customers and the supply chain The shop floor at Aztalan Engineering, Inc. (AEI—Lake Mills, WI) looks to have nearly everything a CNC machinist could want: Multi-axis horizontal milling centers with automatic tool changers and chip removal systems. Four vertical machining centers with 10,000 RPM spindles. Single spindle/single turret and twin spindle/twin turret lathes; equipment with live tooling; equipment with robotic load/unload arms. To look at all this, you’d think that workers at AEI did nothing but cut and mill metal all day. Not so, notes Jim Hale, general manager at AEI. “All this precision cutting and milling requires careful planning and tracking.” During the course of a day’s work, technicians assemble quotes for parts, analyze proposed designs for their manufacturability, establish process controls for parts being manufactured, and communicate with customers and the supply chain. Last year, Hale found a valuable ally to help him execute these tasks more efficiently: Design for Manufacture and Assembly (DFMA®) software, from Boothroyd Dewhurst, Inc. (Wakefield, RI). The software helped Aztalan produce accurate and detailed quotes, explore design and manufacturing strategies, assess manufacturability, decrease manufacturing costs, and effectively manage in-house machining, their customers and their supply chain. “A major customer gave me a half-day demo of DFMA in 2008,” Hale says. “Now it’s central to a lot of what we do.” How DFMA works for quoting and analyzing manufacturing costs DFMA software is a combination of two tightly integrated, complementary tools, Design for Assembly (DFA) and Design for Manufacture (DFM). DFA software makes it possible for engineers to reduce the complexity of a product by consolidating parts into elegant and multifunctional designs resulting in significant cost savings. DFM provides guidance in the selection of materials and processes. Early in design, the software enables engineers starting with either basic, concept-stage shapes or CAD models to evaluate alternative materials and processes. The extensive process library and cost models in DFM Concurrent Costing help to identify major cost drivers such as machining time, part handling (set-up) time, materials costs, or secondary manufacturing processes such as finishing surfaces. Costing, communicating, reviewing Although DFM is all about measuring and comparing costs, AEI uses it in a number of ways, depending on the situation:

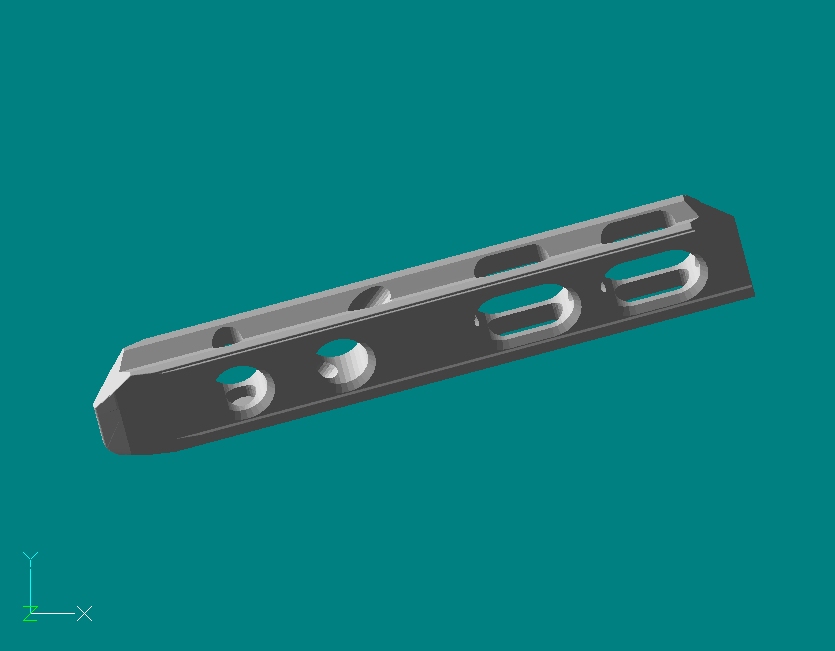

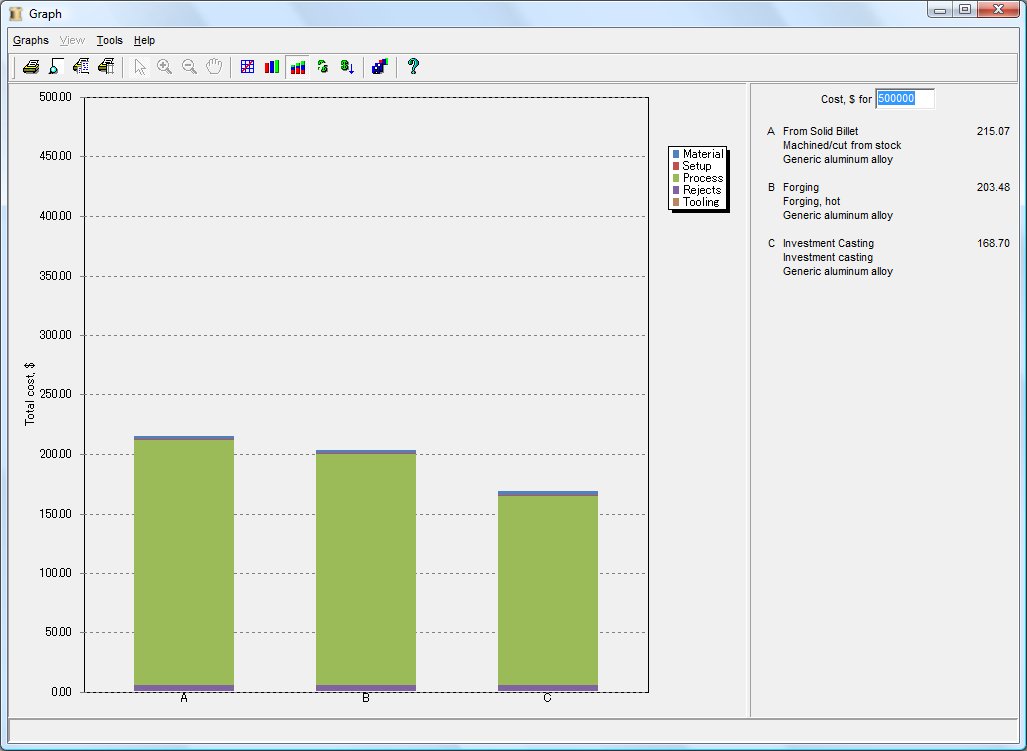

On the level: taking cost drivers out of a complex part Recently, Aztalan prepared a quote for a carpenter’s level (see Figure 1). This particular part was to be produced at a very large volume—hundreds of thousands—so costing it accurately was imperative. The initial proposal called for machining the level out of a rectangular tube of extruded aluminum. The amount of scrap material was considerable. “The aluminum before machining weighed 1 pound. Afterward, the level weighed four-tenths of a pound,” Hale points out. He entered the machining information—because of the high volume of production, the part would have dedicated machines. The machining operations would include high-precision milling of the leveling faces, milling the datums, and precision hole drilling and boring. Hale then printed out an initial costing report for use as a benchmark. “I knew that the part would come in high,” he says. “The main cost driver was not the material—aluminum isn’t that expensive—but the time spent machining each feature.” Hale used his baseline analysis as a starting point for seeing what processes would reduce machining time by creating a near-net part. “The typical starting point for a machined part is a standard size bar, plate, or sheet,” Hale says. “We compare the part geometry to the metal and see how close we are.” If the part geometry is not a close fit to a stock metal size and volume, that may suggest that a better starting point might be investment casting, forging, or another process that produces a near net size and shape and reduces material costs and fixturing and machining times. “The closer we can get to starting from near-net,” Hale points out, “the less metal we cut—and the more costs we save.” Two subsequent analyses—one for forging and one for investment casting—each suggested possible savings (see Chart 1.) Investment casting offered the most savings—21 percent lower costs than the baseline machining estimate. Ongoing processes Aztalan has continued working with its customer to explore cost reductions for the level—everything from different processes to ordering near-net extrusions out of China. DFMA remains part of that process (see Table 1.). “DFMA is a great addition to the services we offer,” Hale says. “When we first purchased the software, I assumed we’d be using it as part of supplier/OEM negotiations. Now it has an important role in how we approach our machining business, from quoting and manufacturing right through to post-op.” One of Aztalan’s goals is to share its machining and DFMA expertise with customers at the concept stage of product development, working with them to create optimized, readily manufacturable designs. He notes, “The earlier we use the software, the more we can build in producibility and cut away their costs.” |