DFMA: Should Costing

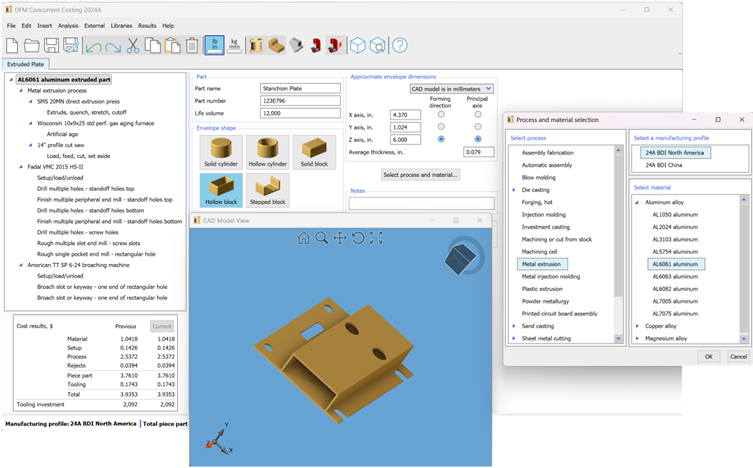

Understand cost drivers early and design to target cost. DFMA: Should Costing provides an immediate, thorough view of manufacturing cost drivers and establishes a benchmark for what your product should cost. Explore alternative processes and materials, specify tolerances and surface finishes, and see cost results update instantly. As you select effective shape-forming processes and refine features, your design becomes cost-optimized.

Every estimate is built from process physics, machine capability, material behavior, and tolerances—so you can show why a part should cost X, not just that it does.

Out-of-the-box libraries let new users generate credible should-costs in days, not months. Customize only where it matters.

DFMA’s guided costing focuses your effort on the few inputs that move the number, so engineers iterate faster and cost teams avoid rabbit holes.

Introduce cost reality at concept and early design to align engineering, sourcing, manufacturing, finance, and suppliers.

Share the specific inputs behind your estimate to drive collaborative, fact-based negotiations—no pressure tactics required.

Benchmark what competitor parts should cost and evaluate make/buy and feature trade-offs even when drawings aren’t available.

Compare should-costs across major manufacturing regions with consistent, pre-loaded country profiles.